PROSPECTUS – The Double Alternator

THE DOUBLE ALTERNATOR

A NEWLY PATENTED TECHNOLOGY

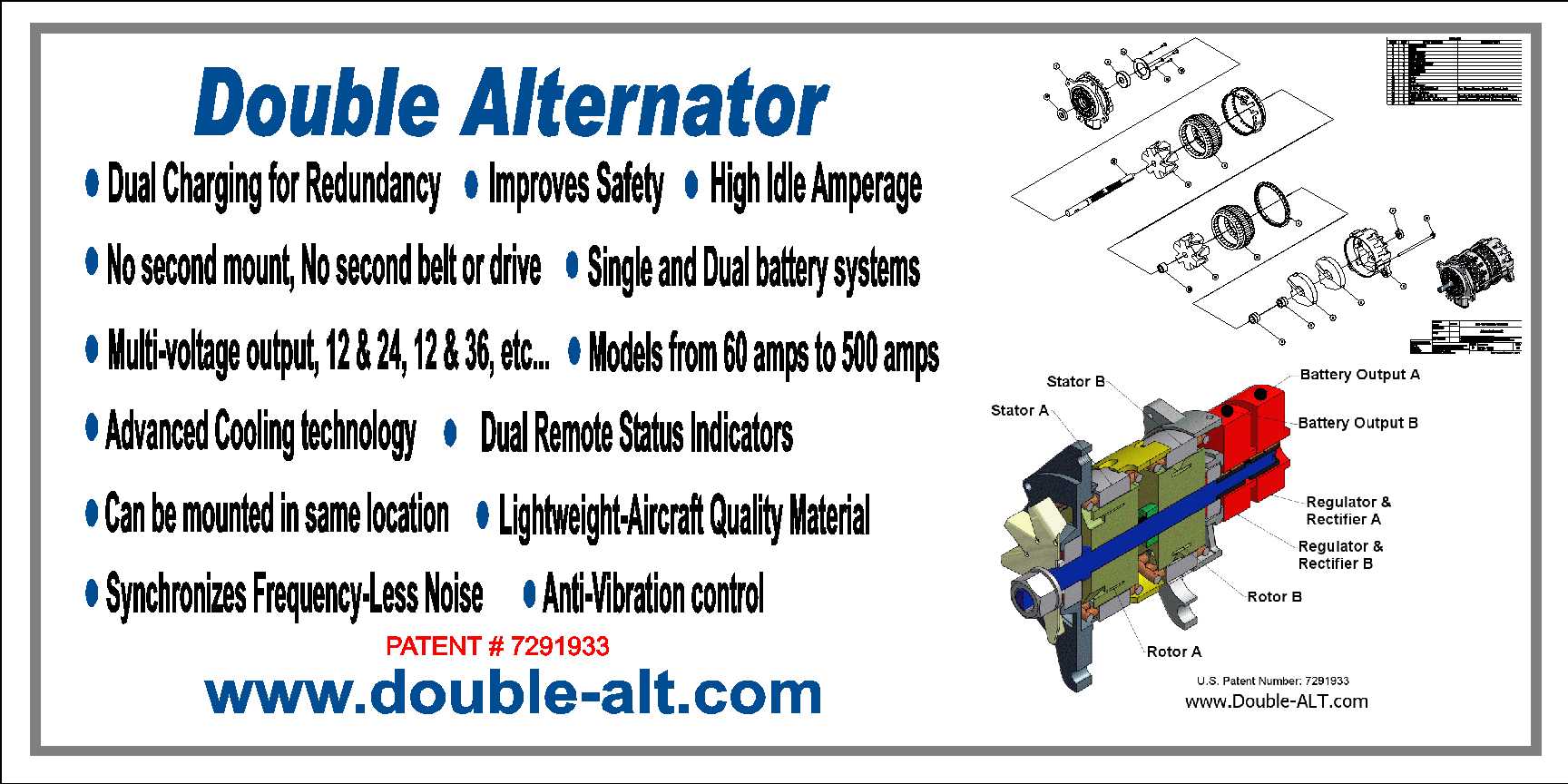

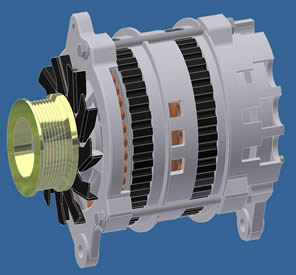

Introducing the Double Alternator, a newly patented technology available for licensing. The Double Alternator is a revolutionary new vehicle alternator and corresponding electrical system that can be used in single and dual battery vehicle systems using the same space and existing mounting hardware. This innovation has all the benefits of a redundant alternator system without any of the disadvantages and is designed for use on trucks, race cars, boats, Farm equipment, heavy equipment, Military, transit buses and virtually any vehicle with a motor run by an electrical system. The design of this Double Alternator is lightweight, durable, cost effective and has the potential to revolutionize the way vehicle owners and operators think about dual alternator systems.

Product Opportunity Summary

This prospectus will introduce the Double Alternator, a newly patented technology available for licensing. The Double Alternator is a revolutionary new vehicle alternator and corresponding electrical system that can be used in single and dual battery vehicle systems using the same space and existing mounting hardware. This innovation has all the benefits of a redundant alternator system without any of the disadvantages and is designed for use on trucks, race cars, boats, Farm equipment, heavy equipment and virtually any vehicle with a motor ran by an electrical system. The design of this Double Alternator is lightweight, durable, cost effective and has the potential to revolutionize the way vehicle owners and operators think about dual alternator systems.

Many vehicles are equipped with redundant alternators to provide power should their main alternator fail; or to aid in the powering of aftermarket accessories that put increased demands on the factory charging system. Today’s vehicle electrical systems are complex and it is sometimes questionable if OEM charging systems will be equipped to handle an increased load. Dual alternator systems currently in use unnecessarily duplicate alternator parts and mounting hardware, which can be pricey. Typical dual alternator installations sometimes require the installation of an auxiliary battery and this combination adds a significant amount of weight to the vehicle which can be problematic, especially in aircraft. Many of these systems also suffer the disadvantage that the current produced by one alternator cannot be cross fed to power a single battery.

The Double Alternator described in this Prospectus and corresponding patent provides a design that alleviates the problems associated with systems currently being used today with a dual alternator electrical system that is lightweight, reliable, inexpensive to manufacture, simple and cost effective. This system has been thoughtfully designed to be mounted on a motor using existing hardware in the same location as a conventional alternator, adding minimal weight to the vehicle.

The Double Alternator (pictured below) is suited for use in single or dual battery systems and in systems that provide cross feed capability between dual electrical power circuits. In dual battery systems, the Double Alternator is capable of replacing existing production of motor-charging engines. An example of this would be replacing a 90 amp alternator and 500 amp single battery system with a Double Alternator that provides two 250 amp batteries and two 45 amp alternators using the same space as the existing system, and capable of control via voltage regulators, whether internal or external or one of each.

The Double Alternator not only provides reliable back up charging power for a variety of purposes, but also improves safety and will delay maintenance of the vehicle charging electrical system. Users of dual alternators and those who are considering the installation of the same will appreciate the unique design of this system as it not only improves upon current methods but offers money, space and weight saving benefits as well.

The Double Alternator can be used on any vehicle with a motor run by an electrical system. The target market for this product is enormous and includes trucks, Farm equipment, SUVs, tractor trailers, single-engine boats, high performance vehicles such as race cars, transit buses, Military vehicles, such as hummers and trucks, emergency vehicles, high end autos with alternator engine powered electrical systems. In addition heavy, off-road construction equipment is also included in the target market.

According to the latest information from the US Bureau of Transit Statistics there are 250,851,833 registered passenger vehicles in the US. Out of these roughly 251 million vehicles, 135,399,945 were classified as automobiles, while 99,124,775 were classified as “Other 2 axle, 4 tire vehicles,” presumably SUVs and pick-up trucks. Yet another 6,649,337 were classified as vehicles with 2 axles and 6 tires and 2,169,670 were classified as “Truck, combination.”

|

The Double Alternator is capable of multi-voltage output, such as 12 volt and 24 volt, 12 volt and 12 volt, 6 volt and 12 volt and many more. As well it is capable of multi-voltage amperage such as 12 volt at 70 amps and 150 to 200 amps at idle on mid size units. |

|

|

In many states emission laws require big-rig trucks to be equipped with a system that automatically shuts the engine down after it idles for only 5 minutes |

in a parallel fashion. If one half of the Double Alternator fails, it can crossbar to

the other half and continue.A second way, is our Regulator Controller, that provides equal loads to each side of our Double Alternator. Some of the details are Proprietary. It has a failsafe design.

Those who operate semi-trucks will particularly appreciate the benefits offered to them by the Double Alternator, as it will enable them to continue basic operations over an extended period without keeping the vehicle idling.. For example: many truckers today operate a 48 volt DC battery operated heating and AC system while parked. This type of system can run for hours saving fuel and engine time, while outputting no emissions. The Double Alternator can charge the trucks normally 12 or 24 volt electrical system and recharges this 48 volt bank of batteries before the next stop.

The Double Alternator can be marketed through existing distribution channels comprising of thousands of outlets including 40,116 auto supply stores. The product is also suited for distribution directly to consumers direct response television, and other avenues.

|

Double Alternator At A Glance Patent Number: United States Utility Patent No. 7291933 Industry: Automotive Target Market Size: 243,707,739+ Primary Use: Double Alternator Key Benefit: Redundant charging for all motors needing electrical systems |

With an expected low manufacturing cost, the margins are good for both the manufacturer and retailer. High gross earnings could be easily attained with this product. Financial projections are contained in Section V. Retailers are expected to be eager to place sizable initial and follow-up orders to capitalize on the exclusiveness this value-added product offers.

Competitive Landscape

The Double Alternator will enter the market with the distinct advantage of being the only alternator on the market to offer a dual system which does not add weight to the vehicle and does not require additional, costly hardware. To get the advantage of a redundant alternator current vehicle owners must literally install two alternators and often times two batteries, in effect duplicating the entire system, to realize the full effect of a dual arrangement. Two batteries are necessary because the current produced by one alternator cannot easily be cross fed to power a single battery. This takes up space, adds a significant amount of weight and is cost prohibitive. The Double Alternator has been designed to offer all the advantages of a dual system with none of the disadvantages.

The Licensee of the Double Alternator will reap the financial and branding benefits for years to come for being the first to market this advanced technology with the following distinct features and benefits:

Product Features and Benefits

-

Reliably supplies electrical current to motor vehicle

-

Offers dual charging and power benefits

-

Requires no duplication of alternators (no second mount, no second belt).

-

Can be used in single and dual battery systems

-

Cross feed capable

-

Replaces existing production of motor-charging engines in dual battery systems

-

Can be controlled by internal or external (or one of each) voltage regulators

-

Automatic or manual shut down of ½ the unit, allowing sufficient time to get the vehicle to a repair shop.

-

Multi-voltage output (12 & 16, 12 & 24; 12 & 12; 24 & 24 vdc etc.. any combination)

-

Multi-amperage output (12v at 160 amps & 24v at 70 amps etc. – any combination)

-

Advanced technology cooling. Cools 50% better. More air flow, better venting.

-

Vibration control for reliability

-

New brush wear technology. Less amps needed.

-

Remote status indicators. (indicates partial failure, over/under voltage-amperage)

-

Improved fasteners. (aircraft quality)

-

Lightweight. Double alternator and two Batteries can be less than OEM, cross fed for engine starts.

-

Each Battery can be ½ size of original OEM. Save weight and cost.

-

Can be mounted in same location as conventional alternator.

-

Mounts on one engine mounting leaving mount open for other equipment(such as Air compressor or 2nd A/C Compressor).

-

Mounts with existing hardware in most cases.

-

Synchronizes frequency/waveform output (less noise from alternator output for vehicles with two-way radios such as police and fire vehicles and aircraft)

-

Inexpensive to manufacture.

-

Improves safety.

-

Delays maintenance of vehicle charging electrical system.

-

Very Large market

-

High Amperage at Idle RPM

Comparable Established Products

Dual alternator kits like the one pictured below are not uncommon, especially as consumers continue to add vehicle options that work to drain the battery charge, such as heating and cooling systems that continue to run when the vehicle is not moving and the battery is not receiving a continual charge. Another emerging trend in vehicle electrical power generation are high powered alternators such as the one pictured to the right that are capable of handling increased electrical demand. These alternators are typically used to operate exotic, high current demand, auto sound systems and other such aftermarket products.

Old methods Pictured to the left are not very cost effective nor are they efficient.

Patent # 7291933 covers all Brushed Alternators, Voltage, Current and Type.

Research indicates there are no products in production or on the market which offer a comparison in either design or function as the Double Alternator as it is described in the Prospectus and the corresponding patent.

Competitive Summary

|

Double Alternator Market Comparison |

||

|

Feature |

Double |

Competitive Products |

|

Reliably supplies electrical current to motor vehicle |

YES |

Most |

|

Offers dual charging and power benefits |

YES |

NO |

|

Requires no duplication of alternator parts |

YES |

NO |

|

Can be used in single and dual battery systems |

YES |

NO |

|

Cross feed capable |

YES |

NO |

|

Replaces existing production of motor-charging engines in dual battery systems |

YES |

NO |

|

Can be controlled by internal or external (or one of each) voltage regulators |

YES |

NO |

|

Automatic or manual shut down of 1/2 the unit, allowing sufficient time to get the vehicle to a repair shop |

YES |

NO |

|

Multi-voltage output (12 & 16, 12 & 48 etc…) |

YES |

NO |

|

Multi-amperage output (12v at 70 amps & 24v at 30amps etc…) |

YES |

NO |

|

Advanced technology cooling |

YES |

NO |

|

Vibration control for reliability |

YES |

NO |

|

New brush wear technology |

YES |

NO |

|

Remote status indicators & Improved fasteners |

YES |

NO |

|

Lightweight |

YES |

NO |

|

Can be mounted in same location as conventional alternator |

YES |

NO |

|

Mounts on one engine mount leaving mount open for additional equipment |

YES |

NO |

|

Mounts with existing hardware |

YES |

NO |

|

Synchronizes frequency/waveform output (less noise from alternator output for vehicles with two-way radios such as Police, Military, Fire vehicles and Aircraft). |

YES |

NO |

|

Inexpensive to manufacture |

YES |

Some |

|

Improves safety |

YES |

NO |

|

Delays maintenance of vehicle charging electrical system |

YES |

Some |

|

Large Market |

YES |

Yes |

|

12 diodes |

YES |

1 |

|

4 Brushes |

YES |

NO |

|

External Checking of Brushes |

YES |

1 |

|

High Amperage at Idle |

YES |

NO |

Industry & Market Analysis

In the U.S., the 2006 market was approximately 16.4 million cars and light trucks sold. Production in North America, including cars and trucks of all types, totaled 11.8 million produced in America, 2.6 million produced in Canada and 2 million produced in Mexico. Globally, about 49 million new cars were sold in 2006.

There are approximately 240 million vehicles in operation in the United States. Around the world, there are approximately 800 million cars and light trucks on the road this year. By 2020, that number will reach 1 billion.

American drivers continue to embrace the notion of customization and personalization, having purchased a record $36.72 billion worth of specialty automotive products in 2006. The number represents a 7 percent increase over 2005, when sales reached $34.28 billion.

Between 2001 and

2006, the market exhibited solid growth of 18 percent in inflation-adjusted dollars. The increasingly diverse U.S. population demonstrates increased minority participation in car culture. These factors will also help drive the market forward.

As an industry, automotive specialty equipment is often lumped into the automotive aftermarket. This is often an incorrect assumption as nearly all of the products produced, sold and installed by the industry are not just replacements for existing vehicle components.

Unlike the automotive aftermarket (repair and replacement parts), automotive specialty equipment products are not purchased out of necessity but rather out of choice—or not so much out of need but of want. As a result, industry sales have grown at rates that are two and three times what might be expected. During the last 10 years the industry has had annual increases averaging nearly 7.4 percent per year, while the U.S. economy (as measured by Gross Domestic Product—GDP) has had an average percent. In comparison, the total automotive aftermarket grew at an average annual rate of 4.5 percent (see chart left).

Now is the perfect time for a product like the Double Alternator to ride the heels of this $36 billion dollar per year trend.

Special Vehicle Industry:

The special vehicle Industry has matured into a multi-faceted, highly competitive business. Gross annual revenue exceeds $1,000,000,000.00 for the upper-echelon builders. These companies fund extensive engineering departments with degreed specialists in every sub-area of the vehicle. Most consumers have no idea about the millions of dollars and hundreds of thousands of man-hours that are expended to develop today’s platforms. The paradigm of carryover technologies limits how close a design can get to a truly optimal subsystem configuration. However, in practical application there is no question that these carryover technologies have been specifically tailored for, and by Off-Highway Vehicle design teams. Sales last year to consumers and branches of the government reached $10.7 billion.

Included in this industry is the market for special services and homeland security vehicles. Since 9/11, one of the constants mentioned in the news and within national and local governments has been homeland security.

Some of the leading manufacturers in this market are already known for their previous work with fire departments and police departments or as suppliers to the U.S. or Canadian military. However, a great deal of these companies are relatively new to this market because they are adapting products from other markets, such as van bodies, semi trailers and buses, to security work. With that said this is a highly fragmented business, with 104 identifiable players spread across the U.S. and Canada. A key characteristic of this industry is the high degree of customization, with manufacturers building products per the specifications of the customer. If a manufacturer can build one unit for a client, it can attract other customers if they are looking for a “similar” unit. Types of vehicles include:

Target Market Analysis

For the purpose of this Prospectus the target market for the Double Alternator is comprised of, but not limited to, the following:

6,649,337 tractor trailers

Truck combinations 2,169,670Race Cars-86,000

Boats-12,746

Buses-83,080

Off-road heavy duty equipment ( no statistics information except a 2007 revenue of $18.8 billion)

Special Vehicles/Military Vehicles- (no statistical data except a yearly $10.7 billion revenue)

Emergency vehicles (48,384 ambulances, 142,400 fire trucks and 900,000 police vehicles)

Motorcycles-6,227,146

In addition this product is suitable for use on heavy duty military vehicles, farm equipment and other heavy duty equipment not specifically tracked in statistical reports. Today, we see more and more mainstream consumers retaining their vehicles. These factors all contribute to a receptive market for the introduction of a unique and useful product like the Double Alternator, making it the ideal time for a quick-to-market approach.

Distribution Channels

The Double Alternator will be primarily distributed in the United States through the Original Equipment Manufacturer (OEM) and through retail outlets including automotive parts and accessory stores such as Auto Zone and Advanced Auto. Other opportunities for offering the products to consumers are trade publications, direct mail and direct-response television. Opportunities to distribute this product are phenomenal and would enable the licensee to take financial advantage of this large global market.

Autozone, Inc., the No. 1 auto parts chain in the U.S., operates more than 4,000 stores and opens approximately 100 to 200 new stores each year. According to Hoover’s Online, Autozone reported sales of $6.17 billion for fiscal 2007 ending in August. Genuine Parts Company (GPC) operates about 1,100 NAPA Auto Parts stores in more than 40 U.S. states. For fiscal 2007 ending in December, Genuine Parts posted sales of $10.8 billion.

Advance Auto has turned auto parts retailing into less of a one-company race. The company is now the number 2 chain after its 1998 acquisition of Sears and Roebuck’s Western Auto Supply and its 2001 purchase of Discount Auto Parts. Advance Auto Parts operates more than 3,100 stores in 40 states. Sales to commercial customers including garages, service stations, and auto dealers account for about 20 percent of revenues. The company is also a partner in online auto parts seller PartsAmerica.com. Advance Auto reported sales of $4.8 billion for fiscal 2007 ending in December.

O’Reilly Automotive sells aftermarket parts, automotive tools, professional service equipment and accessories through more than 1,830 stores and through its website. O’Reilly deals with do-it-yourself customers and professional installers and sells new and remanufactured auto parts, maintenance items, accessories, and a full line of auto body paint. Advance Auto reported sales of $2.5 billion for fiscal 2007 ending in December. The success of these and similar worldwide companies is expected to continue into the future and therefore, the introduction of the Double Alternator into their line of products is well timed.

Product Analysis

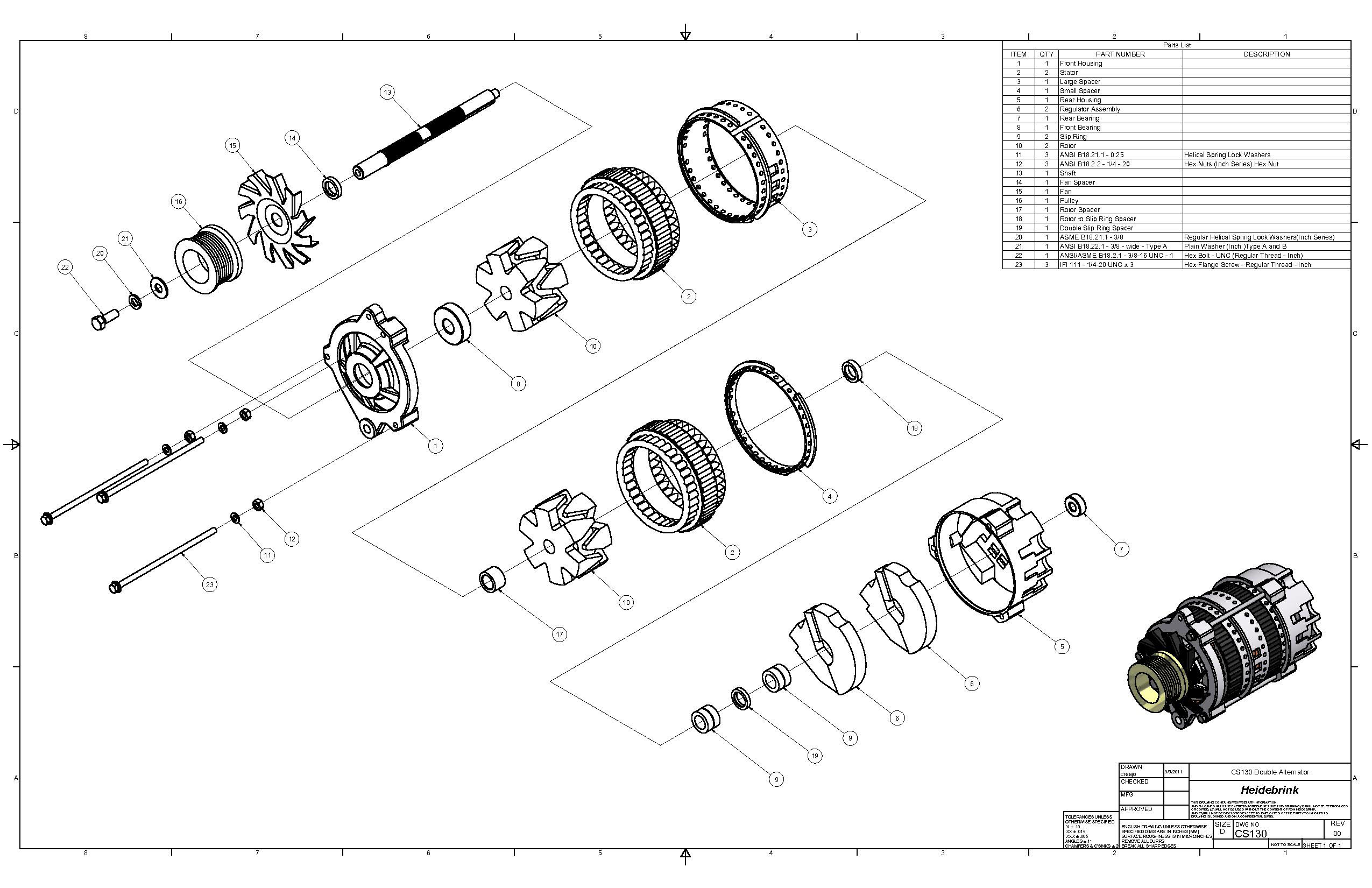

Product SpecificationsAs shown below the Double Alternator is comprised of a housing with an adapter housing and is disposed between the front and rear housing sections and a drive assembly with a rotatable shaft is journalled in bearings and fitted in the housing. A pulley is fixed radially to the shaft for receiving a belt driven by the vehicle motor. Also included is a pair of rotors with each including field windings fixed radially to the shaft for rotation within one of a pair of stators with windings across which voltage is induced by rotor windings. Two sets of slip rings encircle the shaft with one of each of the set electrically connected to one of the rotor windings and insulated from the other slip rings and the shaft. Each one of a pair of three-phase full wave rectifiers is connected to one of the stators and a pair of voltage regulators controls DC voltage output. Each half of the double alternator comprises a rotor, stator, slip rings, brushes and rectifier.

In operation, from an ignition key or switch, voltage is sent to an over voltage relay to a regulator. The regulator adds positive voltage to a field wire, positive voltage to the brush and the positive slip ring to the rotor winding. Voltage flows back out of the rotor to a negative slip ring to a negative brush to ground. This circuit field/rotor is turned on and off by the regulator, which monitors the output volts. A spinning rotor with voltage creates a magnetic field. The stator windings are energized by the magnetic fields and produces voltage pulses to the rectifier. Rectifier output goes to the positive lead battery. Negative diodes are necessary for D.C. current in this system which is done by the halves separately and at the same time.

The foregoing is a broad description of the Double Alternator and should not limit suitable modifications which fall within the scope if the patent. More detail and further embodiments can be found within the text of the patent.

Licensing Opportunities & Patent Information

Currently, we are seeking long-term unique market licensing arrangements involving the patent to make, use, manufacture, market, and distribute this new technology based on the acquisition of the intellectual property rights for each market. Please contact Mr. Ron Heidebrink to discuss this rare and lucrative new product opportunity.

Patent Information

Mr. Ron Heidebrink holds United States Utility Patent No. 7291933 filed on April 11, 2007, and issued on November 6, 2007. This patent for the Double Alternator expires in 2027, commensurate with the filing date. This patent has 19 claims that protect the exclusive design and function of the Double Alternator.